DIY Antibiotic Mixer

Last updated 11/18/2025

Introduction

Antibiotics, especially piperacillin/tazobactam (Zosyn), can be notoriously difficult to reconstitute, often forming a stubborn, gummy plug that requires frustratingly aggressive hand-mixing. For Zosyn alone, this process usually takes a tedious 5 to 10 minutes of intense manual effort per vial. While other vortex mixers exist on the market, they are often bulky, expensive, and designed for large research laboratories. The DIY Antibiotic Mixer was built as a highly compact and far cheaper alternative, specifically tailored to unit needs, bringing the reconstitution time down to less than a minute and saving you significant time.

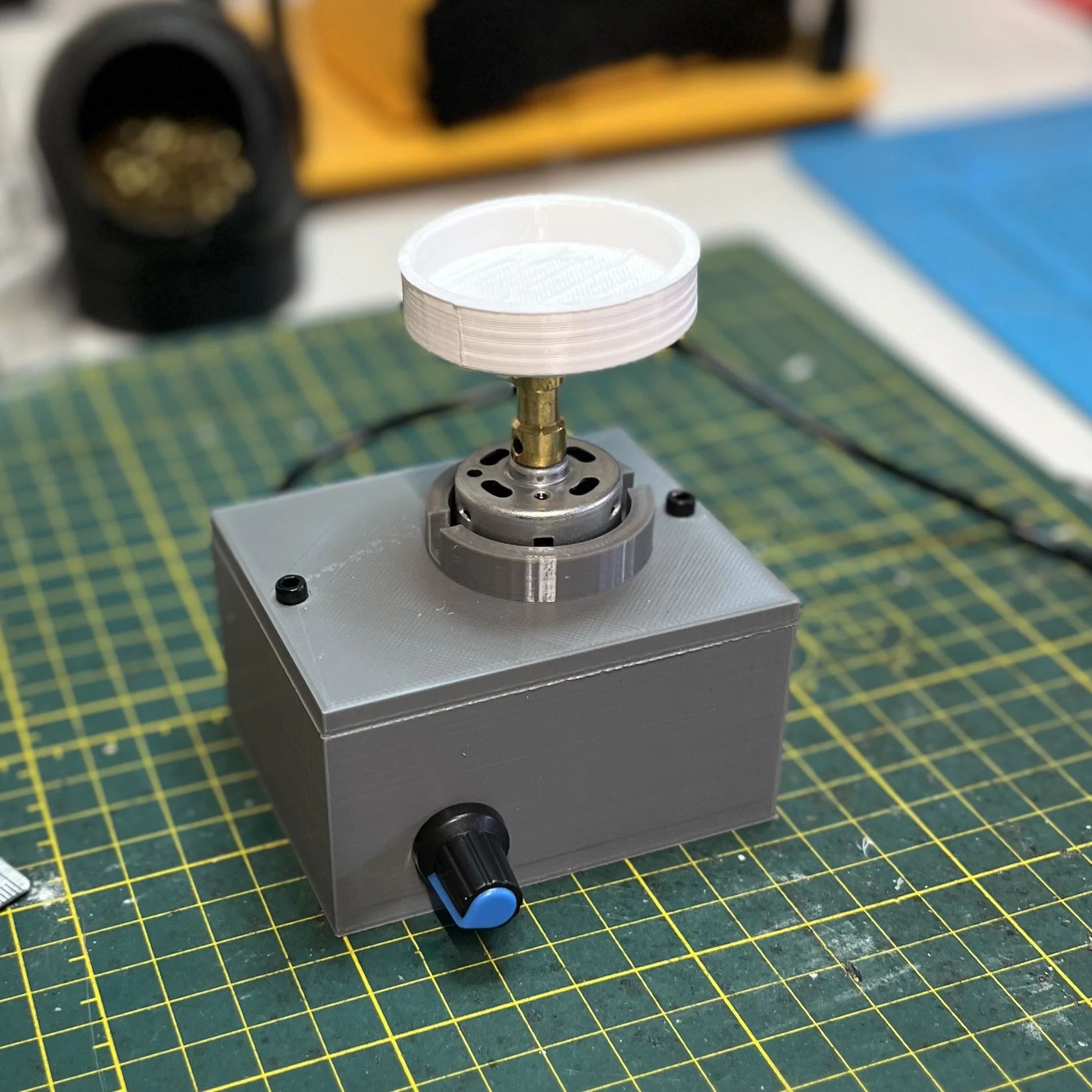

Construction and Core Components

The DIY Antibiotic Mixer's construction relies on converting the high-speed rotation of the motor into stable, powerful orbital motion using several key components:

1. The Motor and Drive System

The High-Speed Engine: The mixer is driven by a 12VDC motor capable of up to 12,000 RPMs. This extreme speed is crucial for generating the vortex.

Speed Control: A mini DC motor PWM Speed Controller is used to modulate the power signal, allowing the user to precisely control the motor's speed and turbulence. Power is delivered via a DC jack. This operates on 12V DC.

Wiring: Electrical connections between the power source, the PWM controller, and the motor are made using spare guitar wire, which is suitable for carrying the necessary current.

2. Orbital Converter (The Wobble Creator)

Housing: The main enclosure, or box, is printed and houses the motor and electronics.

Shaft Adaption: The motor's original shaft is connected to a larger diameter rod using a 2.5mm to 5 mm metal coupling. This secures the motor shaft to a rigid rod that serves as the drive shaft.

Integrated Eccentricity: Instead of a separate eccentric mass, the mixing platform is 3D printed with its central connection hole offset by 2 mm from the platform's geometric center. When the 5 mm rod is inserted and coupled, this offset forces the platform to move in a 4 mm orbital path, directly generating the high-speed wobble needed for mixing.

3. The Platform

The 3D printed platform is the final component in the drive train and is the surface the Zosyn vial presses against to transfer the high-speed orbital energy to the liquid inside the vial.

How to Use the DIY Antibiotic Mixer

The operation is simple and much faster than manual mixing:

Reconstitute: Add the required diluent (usually sterile water or saline) to the Zosyn vial.

Power Up: Turn on the mixer using the PWM speed controller and set it to a low or medium speed to begin the mixing action.

Mix: Press the bottom of the Zosyn vial firmly and steadily against the center of the platform. The orbital motion instantly transfers to the liquid, creating a powerful vortex that rapidly dissolves the stubborn powder plug.

Stop: Once the solution is clear, lift the vial and turn the mixer off.

Current Drawbacks and Solutions

While the DIY Antibiotic Mixer is highly effective, the current prototype has a few limitations that require future adjustments.

Platform Wear: The mixing platform is made of PLA plastic. While PLA is easy to print, it is a relatively soft material and will likely break down over time due to the high-frequency vibration and constant friction from vials. Replacing it with a tougher material like PETG or ABS in the future would improve longevity.

High-Speed Wobble: When the motor is fully engaged and spinning at its highest RPM, the sheer force of the eccentric offset can cause the entire unit to wobble excessively. This is a phenomenon known as "walking." To counteract this, securing a sheet of microsuction fabric (or similar non-slip, high-friction material) to the underside of the unit's base will significantly increase the grip on the benchtop, helping to stabilize the mixer even at high speed.

Denigrating Effects on the Medication: The high-speed orbital motion of the DIY Antibiotic Mixer raises valid questions regarding the potential for drug degradation. While there are extensive research papers detailing how high-shear forces, rapid agitation, and the air-liquid interface can critically damage biologics and protein-based drugs (such as monoclonal antibodies), the risk is significantly lower for simple, small-molecule antibiotics like Zosyn (piperacillin/tazobactam). Since Zosyn is a beta-lactam and not a complex protein, and the mixing time required is less than one minute, the benefits of rapid, complete dissolution outweigh the minimal theoretical risk of shear-induced degradation.

Future Iterations and Enhancements

The next versions of the DIY Antibiotic Mixer will focus on usability and stability.

LED Indicator: A simple user-experience upgrade will be adding an external LED indicator light. This is achievable by simply desoldering the small LED on the PWM speed controller board and running wires to an external LED mounted prominently on the housing. This provides a clear visual signal that the unit is powered on.

Base Weight: Adding significant counterweight (e.g., steel plates or lead weights) to the base will further reduce the wobble and make the mixer safer and more stable at maximum speed, regardless of the microsuction pad.

Material Upgrade: Transitioning the platform material from PLA to a more durable plastic like PETG.